In many buildings and industrial facilities, ventilation systems still rely on traditional belt-driven fans with induction motors, designed at a time when energy efficiency was not a priority. However, with advancements in ventilation technology and regulatory requirements such as ErP 2026, upgrading this equipment has become a key necessity to reduce energy consumption and optimise performance.

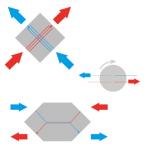

A retrofit involves upgrading an older ventilation system by replacing conventional fans with direct-drive fans featuring EC (electronically commutated) motors. These motors allow for more precise speed control, eliminate mechanical transmission losses, and significantly improve energy efficiency.

|

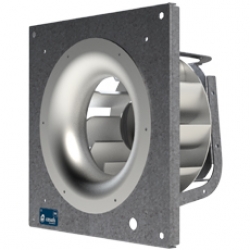

ENKELFAN EEC Centrifugal fan with an EC external rotor motor. [View details on Fanware]. ENKELFAN EEC Centrifugal fan with an EC external rotor motor. [View details on Fanware]. |

|

BOX BV Belt-driven centrifugal fan in a soundproof enclosure. [View details on Fanware]. BOX BV Belt-driven centrifugal fan in a soundproof enclosure. [View details on Fanware]. |

Up to 35% reduction in energy consumption

Efficiency improvement of nearly 50%

Lower maintenance and better airflow control

Case 1: Pharmaceutical industry

A BOX BV fan in an AHU was replaced with 4 ENKELFAN EEC fans, achieving:

➡ Energy consumption reduction: 32.65%

➡ Efficiency improvement: +48.47%

Case 2: Data centre

Replacing an 11 kW BOX BV fan with 4 ENKELFAN EEC fans in a data centre resulted in:

➡ Energy consumption reduction: 31.93%

➡ Extended equipment lifespan

In environments where acoustic comfort and energy efficiency are priorities, choosing a box fans with a low noise level and low SFP (specific fan power) becomes essential. These features ensure a quiet environment and introduce efficiency into the installation, offering a number of significant advantages.

> more information

What is a heat or energy recovery unit and what is it for? Which parts is it composed of? What standards must be met to offer a healthy environment?

> more information