What is SFP and why is it relevant?

The concept of “specific fan power” (SFP) is crucial in reducing energy consumption in ventilation installations because it measures the energy efficiency of the ventilation system.

A low SFP value indicates that the system uses less energy to move a given amount of air, which is essential to minimize energy consumption and operating costs.

What role do box fans play in reducing SFP??

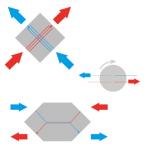

Ventilation boxes or cabinet fans play a vital role in improving energy efficiency. By incorporating high-performance motors and advanced aerodynamic designs, these units can significantly reduce SFP.

Aerodynamic design and efficient motors:

Efficient motors and aerodynamic designs optimize airflow, reducing resistance and therefore the energy needed to move air.

Reduction of energy consumption:

A smaller SFP reduces electrical energy consumption, resulting in more economical and sustainable operation.

Low SFP ventilation boxes, in addition to reducing energy consumption, also improve acoustic comfort by minimizing noise during operation. This improves the comfort and well-being of the building's occupants.

What other aspects help a low SFP in buildings?

In addition to the ventilation system, several components and design practices can contribute to low SFP in a home or building installation:

Aerodynamic duct design:

Well-designed and properly sized ducts minimize pressure losses and resistance to airflow, reducing the energy needed to move air.

Efficient air filters:

The use of low resistance air filters reduces the load on the fans, helping to maintain a low SFP.

Casals ventilation boxes generally carry ISO Coarse≥60% (old G4) and ePM1≥50% (old F7) air filters specifically designed to offer very low air resistance and, therefore, be able to maintain a low SFP regardless of the filtration requirement.

If the priority is energy efficiency and large particle capture, the ISO Coarse filter≥60% is suitable. However, if air quality is paramount and both large and fine particles need to be captured, the ePM1≥50% filter is the best option, despite its greater initial resistance and need for more frequent maintenance.

High efficiency motors:

The implementation of high-efficiency fan motors (such as brushless DC motors or brushless EC) can significantly improve the energy efficiency of the ventilation system. Hence our entire range of

SB-3 EEC and

SBC-3 EEC fans are with EC motor.

Variable speed controllers:

Variable Speed Drives (VSD) adjust fan speed based on demand, optimizing energy consumption.

Rules and regulations applicable to efficient ventilation

|

EN 13779

|

Provides guidelines for the design and operation of ventilation and air conditioning systems in non-residential buildings, including specifications for SFP

|

|

ISO 16890

|

International standard for the efficiency of air filters, contributing to more efficient ventilation systems.

|

|

Energy Efficiency of Buildings Directive (EPBD)

|

European Union legislation that promotes energy efficiency in buildings through energy performance standards and certifications.

|

|

ASHRAE 90.1

|

American Society of Heating, Refrigerating and Air-Conditioning Engineers Standard for Energy Efficiency in Commercial Buildings.

|

|

Passivhaus Standard

|

Provides strict criteria for the energy efficiency and comfort of residential and non-residential buildings, including specific requirements for heat recovery ventilation systems.

|

|

National building regulations

|

Each country may have its own regulations and building codes that promote energy efficiency and sustainability in buildings, such as the Technical Building Code (CTE) in Spain.

|

Consultation of the SFP of the Casals fans in Fanware

In the Casals product selection software,

Fanware, you can find out the SFP curve of all our products. Once you have selected the fan of your interest, activate the SFP curve in the legend and it will appear on the graph.

As you can see, the further to the right the working point is, the greater the flow, the lower the pressure and therefore the lower the SFP.

On the contrary, at the beginning of the curve, as there is greater pressure and lower flow, there is also greater air resistance, which is why the SFP is at its highest values.

From this it follows that the optimal operation of the fan, in terms of efficiency, is at a more central or advanced working point on the graph, where the SFP is quite low and the efficiency curve is at its maximum.

However, the optimal point of the installation will be on the right side of the curve, where we find high flow rates and low pressures.