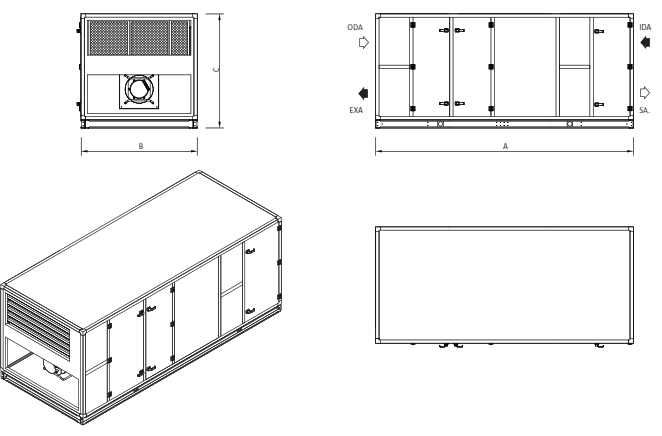

VERTICAL CROSS-FLOW HEAT RECOVERY UNIT WITH EC MOTOR. EFFICIENCY 83%

MANUFACTURING FEATURES

CHASSIS

• Profiles 50 x 50 mm in self-supporting extruded anodized aluminium, with mechanical strength requirements in accordance with EN 1886: D1 (M). Under request: 50mm panel L1 classification.

• 50 mm thick double-walled sandwich type panel with exterior in pre-painted RAL 9010 galvanized sheet steel and interior in hot-dip galvanized sheet steel with interposed insulation made of polyurethane foam with a density of 40kg/m3.

• Opening panels equipped with perimeter hinges made of anticorrosive plastic material and closures with handles for faster and easier access to internal components. The safety microswitches, applied to the inspection doors, allow access only to completely switched off units.

• Structure with seal class L1.

• The thermal bridge characteristic is class T3/TB4 according to EN1886.

HEAT EXCHANGER

• Each unit is equipped with an aluminum counterflow heat exchanger that is used to transfer heat from the exhausted air to the new air. The heat exchange is carried out in cross-flow with an efficiency greater than 80% in dry air.

• Fin spacing is optimized to reduce air side pressure drop and fan power consumption.

• In some conditions of low outside air temperature and high humidity, the exchanger may start to freeze. The units are equipped with a defrost system required in case of very low ambient conditions. The defrost system can either be electric or by hot water.

• The heat recovery is also equipped with an additional bypass damper for free-cooling and free-heat mode management.

• The heat exchanger participates in the Eurovent Certification program and is dimensioned according to the ECO Design specification.

FILTERS

• Each QUANTICA EEC recovery unit is equipped with rigid bag filters: 1 ISO ePM1≥50% (F7) air extraction filter and another ISO ePM1≥50% (F7) air supply filter.

• Optionally, an ISO filter ePM1≥80% (F9) can be requested for air supply.

• Both types of filters are mounted on slides equipped with gaskets to ensure effective sealing.

• Their position, upstream of the internal components, also guarantees their protection.

MOTOR-FAN

• High efficiency plug-fan type. They comply with the requirements of the Ecological Design Regulation No.327/2011 / EU.

• Attached to the support frame using self-centering brackets to ensure the correct distance between the impeller and the nozzle to optimize performance. All the fans are driven by electronically commutated motors (brushless EC), thermally protected and regulated by a 0-10V modulating signal to ensure that the most suitable performance is achieved for the needs of the system, optimizing performance.

ELECTRONIC CONTROL

• Supplied with an advanced electronic display, which includes temperature probes in the external air intake and the ambient air intake, which supervises their operation. The user interface consists of a remote control panel with an LCD screen.

• There are 3 control modes, all with Modbus communication protocol to integrate the unit in the most modern home automation systems through the RS485 serial port, supplied as standard.

• Control BASIC

• Control EVO COP (Constant pressure)

• Control EVO CAV (Constant airflow)

BYPASS

• Automatic total bypass (100%).

RANGE

• 5 construction sizes.

• Circular inlet connection Ø355 and Ø400 for models 045 and 060; rectangular inlet for the rest of sizes.

• Vertical configuration.

• Flow-rate up to 4.500 to 13.000 m³/h.

• Not configurable.

• 3 controls with Modbus.

APPLICATIONS

• Designed for outdoor installation for residential, commercial and industrial environments.

• In full compliance with the requirements of Ecodesign Regulation No. 1253/2014/EU, in force since January 2018, the devices in the QUANTICA EEC range guarantee high standards of comfort and health in enslaved environments, optimizing the general energy balance and against a particularly low power consumption.

• Suggested minimum outside temperature of -5°C.

| A | B | C |

|---|---|---|

| 3580 | 1500 | 1700 |

MANUFACTURING FEATURES

• Circular outdoor flange with bird guard made of galvanized steel.

Duct sensor for measuring temperature, relative humidity and CO2 in the rooms.

Optional: The CO2 modules can be removed from the sensor to be calibrated.

The sound attenuators are used to absorb the noise in air conditioning or ventilation ducts.

Casing in galvanised steel, thickness 0,8 mm;

Mounting flange with quick attack;

Acoustic material in mineral wool 50 Kg /m³ with protection against erosion by glass fibre fire resistance M0 and extended metal sheet

UNDER REQUEST:

Stainless steel execution

• SENSOR

Temperature:

• Sensor type: NTC.

• Measuring range: 0.0ºC to 50.0ºC.

• Sensor life: >10 years.

RH:

• Sensor type: capacitive with integrated electronic circuit.

• Measurement range: 0% to 100%.

• Sensor life: >10 years.

CO2 (carbon dioxide):

• Sensor type: NDIR (Non-Dispersive Infrared detector). Dual sensor.

• Measurement range: 0ppm to 2000ppm.

• Sensor life: >5 years.

• Note: factory calibrated sensors. CO2 sensors calibration function.

FUNCTIONS

• Control function of the start/stop of the air purifier/Fan by means of digital output by voltage-free relay contact.

• Regulation function on the CO2 of a fan with EC technology or a damper with 0-10V signal.

• Hourly and daily programming with two time slots per day available.

• Environmental measurements of temperature, relative humidity and CO2

• 0… 10V analog outputs for environmental measurements.

• CO2 Measurement range: 0ppm to 2000ppm 0ppm: 0.0V ... 2000ppm:10.0V

• Electrical supply voltage: 100… 250V

• Modbus serial communication channel for integration in centralized systems (BMS).

• Mounting in an indoor environment. Mounting base prepared for universal mechanism box.

•Easy connection: Plug & Play.

Filtration for air treatment units equipped with a pre-filter upstream, and air-conditioning units.

• High filtration area, high efficiency, compact and economic filter.

• Media: Mini pleat fiberglass paper

• Frame: Galvanized steel

• Maximum T° in continuous service: 100°C

• Humidity: 100% RH

• Tested for food contact according to CE 1935/2004

• Certified for microbial development (ISO 846-VD 6022)

• The automatic defrost system consists of a self-regulating electric coil in PWM mode of the input power, installed on the return air intake.

• The system is controlled by a special temperature probe positioned on the exhaust air and guarantees a considerable reduction of the input power compared to the traditional systems available on the market.

All units may be equipped with an internal re-heating electric battery, made up of armoured steel electric heaters, supplied complete with PWM control system, safety thermostat already wired and installed on board.

All units may be equipped with an internal re-heating electric battery, made up of armoured steel electric heaters, supplied complete with PWM control system, safety thermostat already wired and installed on board.

The hot water coil is manufactured with copper pipes thickness 0,4 mm and aluminium fins thickness 0,11 mm. The pipes are mechanically expanded in the aluminium fins to increase the thermal exchange rate. On request, it is possible to install coils with different capacities from the standard ones, when previously agreed with the factory.

The hot water coil is manufactured with copper pipes thickness 0,4 mm and aluminium fins thickness 0,11 mm. The pipes are mechanically expanded in the aluminium fins to increase the thermal exchange rate. On request, it is possible to install coils with different capacities from the standard ones, when previously agreed with the factory.

The coil is manufactured with copper pipes thickness 0,40 mm and aluminium fins thickness 0,11 mm. The pipes are mechanically expanded in the aluminium fins to increase the thermal exchange rate. On request, it is possible to install coils with thermal performances different from the standard ones, when previously agreed with the factory. The cooling coil section is supplied complete with condensate drain pan with water discharge.

• It consists of a kit including the 3-way valve for the control of the water flow, to be combined with the hot and/or cold water coil, and its modulating electric actuator.

• Connection and fitting devices not included (to be arrange for by the installer).