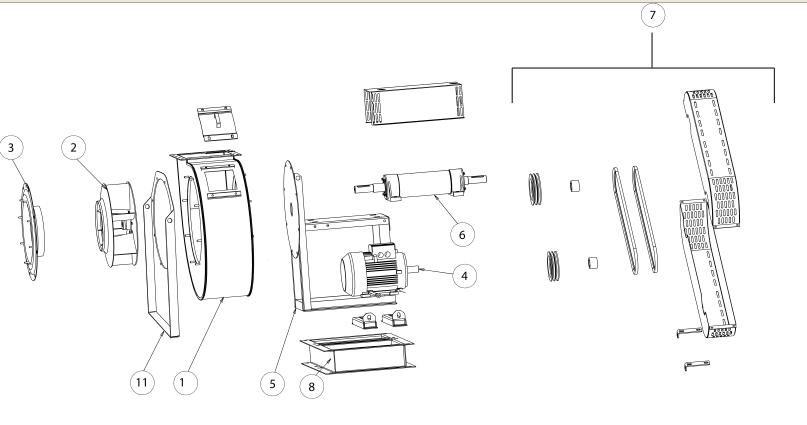

HIGH PRESSURE WITH BACKWARD IMPELLER AND BELT TRASMISSION

MANUFACTURING FEATURES:

• Fan made of Fe360 sheet. The fan paint finish is based on a Qualicoat polyester powder coating stoved at 200ºC, with an average film thickness of 70 microns. Average heat resistence of coating is 180ºC with peaks of 200ºC.

• Fully welded housing.

• High efficiency simple inlet backward impeller with self-cleaning system made of Fe360 sheet statically and dynamically balanced. Impellers are painted with polyester primer that resists temperatures up to 300ºC.

• Motorized fan with base frame (configuration 12). Full equipped fans including: motor, pulleys, belts, belts guard and shaft guard. Fitted over a base plate. IE4 motors for 75kW power or higher.

• It allows adjusting the orientation locally from models 450 to 630. Models sizes from 710 to 1000 size the orientation is fixed.

• Available positions (to be indicated in case of order): LG270, LG0, LG45, LG90, LG135, LG180, LG225, LG315, RD0, RD45, RD90, RD135, RD180, RD225, RD270, RD315.

• The indicated codes correspond to the model in position LG270

APPLICATIONS:

Designed for inline installation, they are suitable for:

• Industrial applications, extraction or injection of air.

• Cooling of machines and parts.

• Exhaust after filters, separators and cyclones.

• Pneumatic transport.

• Slightly dusty air transport.

• Maximum working temperature: carried air: 200ºC, ambient: 60ºC.

UNDER REQUEST

· Fans for 60Hz and special voltages.

· 2 speed motor.

· Fan with free shaft (configuration 1) or with motor supported on the pedestal side (configuration 9).

· C4 coating painting

· Hot dip galvanized

· Special steel (Cor-Ten A, Hardox...)

· Inox 304 (normal or electropolished finish)

· Inox 316 (normal or electropolished finish)

· Cooling wheel

· Anticaloric paint

· Reinforced housing

· Fully welded housing (waterproof)

· Insulated housing

· Split casing (for big sizes)

· Inspection door to facilitate maintenance and cleaning

· Drain plug.

· Airtight axle

· Frontal foot

· Double suction flange

· Available in non-sparking air passage and standard motor.

· Other brands of motors.

| a | A | a1 | a2 | B | b | b1 | b2 | C | D | d | d1 | D1 | d2 | D2 | D3 | D4 | D5 | D6 | D7 | E | F | G | H | H1 | H2 | I | L | M | N | N1xØ1 | N2xØ2 | n2xp | O | O6 | Ø3 | Ø4 | P | Q | R | S | S1 | S2 | S3 | S4 | S5 | S6 | S7 | T | U | V | W | X | X1 | X2 | X3 | X4 | X5 | X6 | X7 | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 146 | 65 | 182 | 216 | 719 | 105 | 139 | 175 | 675 | 300 | 205 | 241 | 393 | 275 | 350 | 375 | 335 | 312 | 319 | 490 | 712 | 285 | 56 | 400 | 300 | 400 | 407 | 28 | 485 | 50 | Nº8 M6x20 | 6x12 | 1x112 | 355 | 190 | 14 | 14 | 400 | 463 | 23 | 375 | 312 | 319 | 300 | 490 | 393 | 350 | 335 | 1060 | 120 | 38 | 660 | 312 | 300 | 490 | 393 | 350 | 375 | 335 | 319 | 80 |

MANUFACTURING FEATURES

• Flexible polyurethane coupling flange with fiberglass fabric to avoid possible vibrations to the installation.

• 160 mm width and supplied with 2 fixing clamps.

• Fire classification: M0.

MANUFACTURING FEATURES

• Flexible joint to clinch the fan to the duct.

• Avoids transmission of vibrations for circular and rectangular connection.

• Dimensions: two metallic flanges of 45mm each one and a flexible flange of 60mm.

• The reel is 30,5m lenght.

• Maximum pressure: 20 mmca.

• Fire resistance M0 from -50ºC to +200ºC in continuous and 400ºC/2h.

MANUFACTURING FEATURES

• For axial (inlet and outlet) and centrifugal (inlet) fans.

UNDER REQUEST

• Versions in stainless 304 and stainless 316.

MANUFACTURING FRATURES

• Inlet protection guard to avoid the entry of objects and contact with the impeller.

• Made of galvanised steel models 7,9, 10, 12 and 15. And the rest of models with polyester powder finishing coat.

MANUFACTURING FRATURES

• Galvanized protection grid on the outlet side to avoid the entry of objects and contact with the impeller.

Frontal feet support for medium ang high pressure fans

MB22/9-28/11 and MB31/12-45/18

Option frontal feet for models between 22/9 and 45/18

MBGR, MTGR*, MBRU, MTRU*, MBRM, MTRM*, MTRL*, MBCA, MTCA*, MBZM P/R and MTZM P/R*

Models of size 560 and above are supplied with a front support foot, for the other models the front support foot is optional.

AATZA*, AATVC*, AATVP*, AATVG/N* and AATVM*

Models of size 710 and above are supplied with a front support foot, for the other models the front support foot is optional.

AAZA, AAVC/N, AAVP/N, AAVG/N, AAVM, AAVA and AATVA*

Opcional frontal support in all models. For models until size 630 it can be supplied as an accessory, formodels of size 710 and above the frontal support is welded and it must be ordered with the fan (under request)

* For system 12 fans a special basefame is needed for installing the frontal support

Generic image, in some models the real foot may differ from the shown image

MANUFACTURING FEATURES

• Specially designed for speed frequency control in ventilation applications.

• Ultra compact, simple operation and wide range of functions.

*Dial panel incorporated. Optional EMC filter.

Certifications: CE/UL/CSA/EN/GOST/CCC.

Protection index IP20.

The selection of SFC frequency drive speed controller must be made based on the maximum intensity absorbed by the fan to be regulated. The powers (kW) and the intensity for constant load refer to the normal duty (150% overload for 60 seconds). The intensity for quadratic load admits an overload of 110% during 60s.

SFC 230: Entrance 230V I, exit 230V III

SFC 400: Entrance 400V III, exit 400V III

EMC filter incorporated for models from 47A (included)

*Lineal load rated current

**Quadratic load rated current

MANUFACTURING FEATURES

• Safety start-stop switches according to IEC 60947-1 and IEC 60947-3.

• IP65 and always equipped an auxiliary contact.

• Useful for switching off the current before handling the fan.

*Máx. thermal current air (A)

MANUFACTURING FEATURES

• Support of great radial and axial elasticity.

• These low-profile, compact and elastic supports control the three directions of movement with large deformations in the rubber.

• It consists of two parallel armour adhered to the bell-shaped rubber and by a base with handles.

• These supports with handles have a threaded hole in their upper frame and are easy to install and fix.

• The steel protection washer allows it to withstand overloads by increasing its rigidity and protects the rubber from dripping hydrocarbons.

• Elastomer type NR or high quality elastomer. Working temperatures between -40ºC and + 70º C.

• Taking into account the tolerances of hardness in the elastomers, the mechanical characteristics of these series may differ.

• Range of 6 sizes and 3 different hardnesses (45-60-75) to fit a load range between 2 Kg and 1300 Kg.

1. Soft: hardness A 45

2. Average: hardness B 60

3. Hard: hardness C 75

APPLICATIONS

• Very appropriate in the elastic suspensions of machines that present vibrations of horizontal components.

MANUFACTURING FEATURES

• Metal insulators designed to work with compression with 85% insulation according to the following arrows (travel in mm) and rpm:

Arrow (mm.) r.p.m.

20 mm >600 r.p.m.

30 mm >500 r.p.m.

• Made of high quality elastic steel, with rectangular base and rubber mat to improve the grip. It treats of a resistant product and easy assembly, that avoids all type of vibrations of the fans to the structure of the premises.

• Operating temperature from -45 ° C to + 120 ° C.

APPLICATION

• To install under machines with rotating components, ventilation groups, fans, ventilation boxes, etc.

Structure made of extruded aluminum profiles available in different dimensions according to the panel to be installed and the fan volume. The profiles joining is made of polyamide corners, which gives them great strength and the possibility of disassembling the structure into pieces.

Panels can be made of a single sheet with inner insulation of 10 mm thick polyethylene foam, or 2 sheets (sandwich panel) with thicknesses of 25 mm or 50 mm, depending on the required attenuation degree.

The sheets of each panel can be galvanized steel, galvanized steel with coloured plastic coating or stainless steel.

The lower part is finished off with a structure / plinth for transport and handling, made of galvanized sheet or upn-80/100 joist, depending on the cabin dimensions and weight.

The air inlets and outlets of the cabin have anti-vibration tarpaulins coupled to mounted fans. These fans rest on a floating base with acoustic dampers.

RRP to consult.

MANUFACTURING FEATURES

• Circular-circular coupling flange through anti-vibration canvas.

• Supplied with two O-shaped plates made of galvanized sheet metal and necessary screws.

| Nº | Code | Family | Name | Qty |

|---|---|---|---|---|

| 2 | T05304500 | IMPELLER | AATVG/N 450 LG | x1 |

| 3 | 505304500SP04 | INLET CONE | AAVG/N-AATVG/N 450 | x1 |

| 6 | 50905000SP01 | PIECE TRANSMISSION | 90 | x1 |