Marine environments present extreme conditions that demand durable and robust ventilation systems.

Challenges such as salt-water corrosion, fluctuating temperatures, high humidity, and confined spaces are constant factors that ventilation equipment must endure.

VENTILATION SOLUTIONS FOR MARINE AND OFFSHORE ENVIRONMENTS

Benefits of ventilation in marine applications:

-

Air quality control: Maintains clean air in engine rooms and cargo holds.

-

Prevention of hazardous gases: Avoids the build-up of flammable or toxic gases.

-

Temperature regulation: Helps dissipate heat generated by critical machinery.

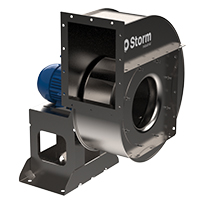

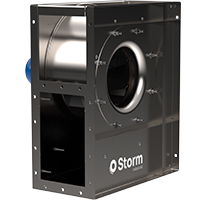

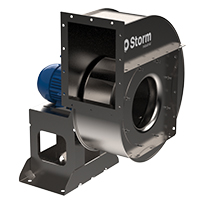

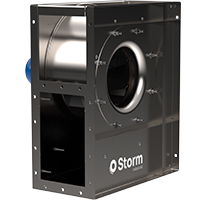

RECOMENDED FANS FOR MARINE APPLICATIONS

|

CENTRIFUGAL |

NIMUS |

NIMAX |

KASTORM |

MBCA |

|

|

|

|

|

AXIAL |

HC and HCA |

HB and HBA |

HM and HMA |

|

|

|

ATEX Fans: In some marine applications, it is essential to install ATEX-certified fans for explosive atmospheres. This is crucial when transporting or storing chemicals or flammable materials that generate potentially hazardous atmospheres. ATEX fans ensure safe operation under these conditions.

ANTI-CORROSIVE FINISHES FOR EXTREME CONDITIONS

Fans used in marine environments must be prepared to withstand highly corrosive conditions. Casals Ventilación offers centrifugal fans made from stainless steel or with marine-grade finishes, such as C3, C4, and C5M, according to the ISO 12944 standard:

-

Stainless steel 304: Recommended for environments with moderate exposure to corrosion, such as the interiors of ships or areas protected from direct contact with extreme salinity.

-

Staintless steel 316: Specifically designed to resist corrosion in highly aggressive environments, such as areas exposed to direct saltwater and highly corrosive atmospheres in offshore applications.

-

C3: Ideal for urban and industrial atmospheres and areas with high humidity.

-

C4: Suitable for industrial and coastal environments, as well as chemical plants.

-

C5M: Recommended for high-salinity areas, such as marine environments, offshore platforms, and coastal zones.

download PDF